PURITY IN ELEMENTS

QCIPL-50: High Purity Catalyst Excellence

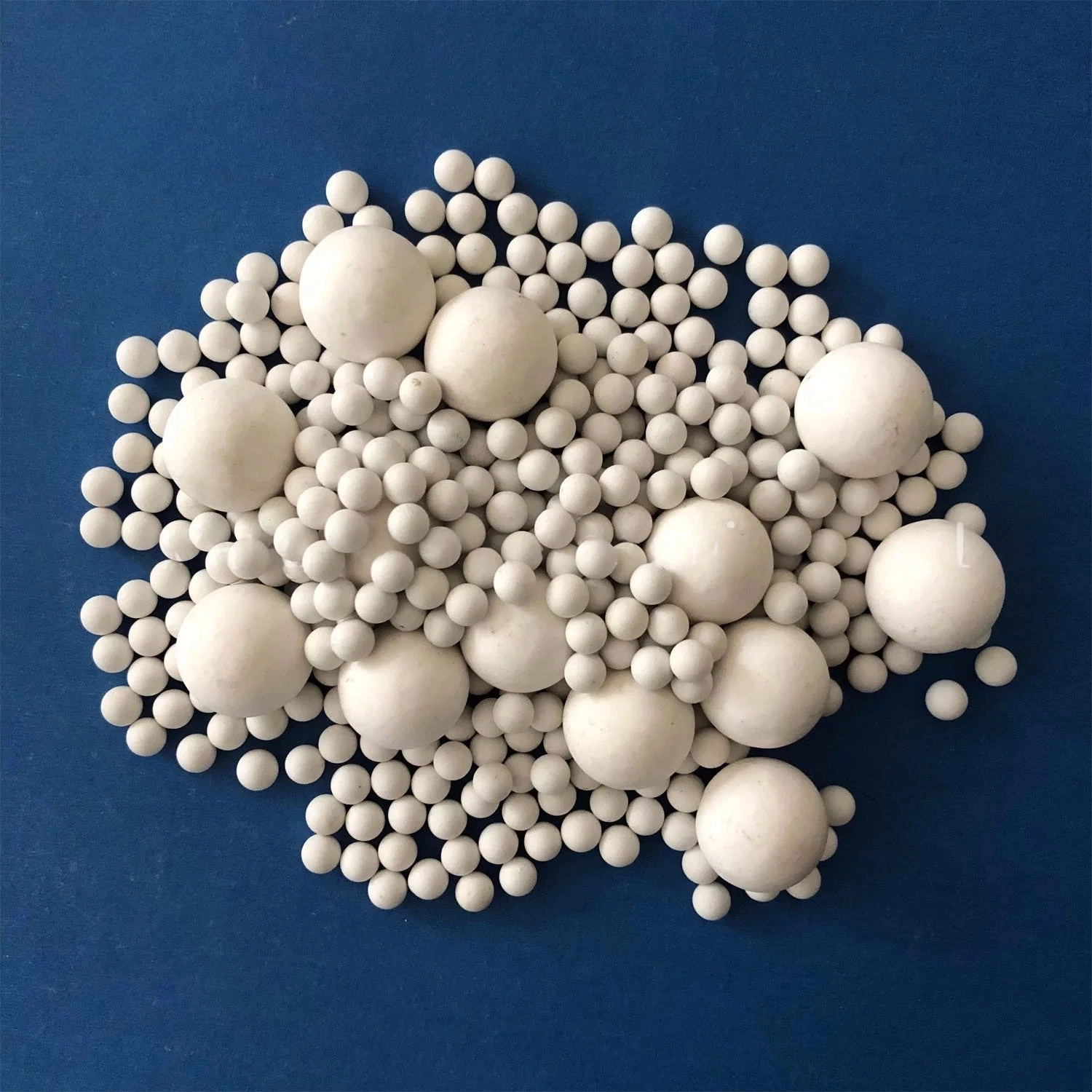

Vishwas Ceramic – Quantum Care Industries Ceramic Balls exemplify exceptional quality. These ceramic balls boast low water absorption, exhibit 100% survival in rapid depressurization tests, showcase high crushing strength, superior impact resistance (drop test), remarkable thermal shock resistance (quench test), and minimal attrition loss.

Today, Vishwas Ceramic – Quantum Care Industries’ ceramic balls find extensive applications in petroleum refining, petrochemicals, fertilizers plants, acid plants, and industrial gas industries.

Quantum Balls are having excellent quality

- Low Water absorption

- 100% survival in Rapid Depressurization Test

- Inert towards liquid water

- High Crushing Strength

- Better Impact Resistance (Drop Test)

- Thermal shock resistance (Quench Test)

- Very low Attrition loss

Ceramic Ball with different grade

- Ceramic ball Low purity - Grade QCIPL-25™ (19-26 % Al2O3)

- Ceramic ball Medium purity - Grade QCIPL-50™ (40-45 % Al2O3)

- High Alumina Ball - Grade QCIPL-99™ (99 % Al2O3)

Chemical Analysis

| QCIPL-50 | |

|---|---|

| Al2O3 | 45 to 52 % |

| SiO2 | 45 to 55 % |

| SiO2+ Al2O3 | - |

| K2O | 2.1 to 3 % |

| Na2O | 0.5 to 1.5 % |

| CaO | 0.5 to 1.5 % |

| MgO | 0.5 to 1.5 % |

| Fe2O3 | 1 % Max |

| Tio2 | - |

| Leachable Iron | - |

Physical Analysis

| QCIPL-50 | |

|---|---|

| Apparent Porosity (By Volume) | <1 % |

| Water Absorption (By weight) | 0.4 % Max |

| Particle Density : (Material Piece Density) gm/cc |

2.4 to 2.6 |

| Working Temp | 1450 oC |

| Roundness, dmax/dmin , mm | <1.25 |

| Thermal Expansion Coefficient, 1/K | 4.9 x 10-6 |

| Spec. Thermal Energy, kj/(kg x k) | ~ 0.94 |

| Thermal Conductivity, kj /(m x h x k) | ~ 7.0 |

| Packing Density : (Weight of balls in one M3 Volume) |

1450 +/-30 Kgs OR 1.42 to 1.48 Kg/L |

Crushing Strength (Point Load):Kgs/lbs/n

| SIZE | SIZE RANGE | QCIPL-50 | ||

|---|---|---|---|---|

| kgs | lbs | n | ||

| 1/8” –3 mm | 2 to 5 mm | >57 | 126 | 558 |

| 1/4” – 6 mm | 5 to 8 mm | >113 | 249 | 1108 |

| 1/2" – 12 mm | 11 to 14mm | >230 | 507 | 2256 |

| 3/4” -- 19mm | 17 to 21 mm | >480 | 1058 | 4707 |

| 1” -- 25 mm | 23 to 27mm | >700 | 1543 | 6865 |

| 1 ½”---38 mm | 34 to 40mm | >1000 | 2205 | 9807 |

| 2” --- 50 mm | 47 to 53mm | >1200 | 2645 | 11768 |

Average Ball Value

| VOID SPACE,% | Void Fraction | SURFACE AREA | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MIN | MAX | % | AVG VALUE | |||||||

| 1/8” – 3 mm | 2 to 5 mm | 42 | 45 | 0.425 | 1250 | |||||

| 1/4” – 6 mm | 5 to 8 mm | 42 | 45 | 0.425 | 500 | |||||

| 1/2" – 12 mm | 11 to 14mm | 42 | 45 | 0.425 | 280 | |||||

| 3/4”— 19mm | 17 to 21 mm | 42 | 45 | 0.425 | 170 | |||||

| 1”---- 25 mm | 23 to 27mm | 42 | 45 | 0.425 | 125 | |||||

| 1 ½”---38 mm | 34 to 40mm | 42 | 45 | 0.425 | 85 | |||||

| 2” --- 50 mm | 47 to 53mm | 42 | 45 | 0.425 | 45 | |||||